Tailored Solutions: Our Implemented Projects

Boiler Water Purification System

In a prominent energy sector plant located in the Canary Islands, we implemented an advanced treatment system that revolutionizes the production of purified water for boilers. This state-of-the-art system utilizes a double-stage reverse osmosis process, ensuring a production capacity of 35 m³ of high-quality purified water

The most remarkable aspect of our solution is the integration of a touchscreen HMI and intelligent sensors, allowing comprehensive monitoring of process parameters through our vigData. With this technology, operators can remotely access data from the cloud, facilitating efficient and precise management.

Automation and full process control are key features of our system, offering new functionalities and significant advantages in production process management. This translates to higher operational efficiency, superior product quality, and increased peace of mind for our customers.

Wine Cellar Ultrafiltration Equipment

In a renowned wine cellar, we conducted the installation of an ultrafiltration machine designed to optimize the production process. Our cutting-edge solution ensures the quality and purity of water consumed in the wine-making process, preserving its distinctive characteristics and ensuring customer satisfaction.

Our system stands out for its ease of use and maintenance, as well as its ability to adapt to the specific needs of the winery. Additionally, we offer monitoring services and continuous support through our platform vigData to ensure optimal operation and consistent results over time.

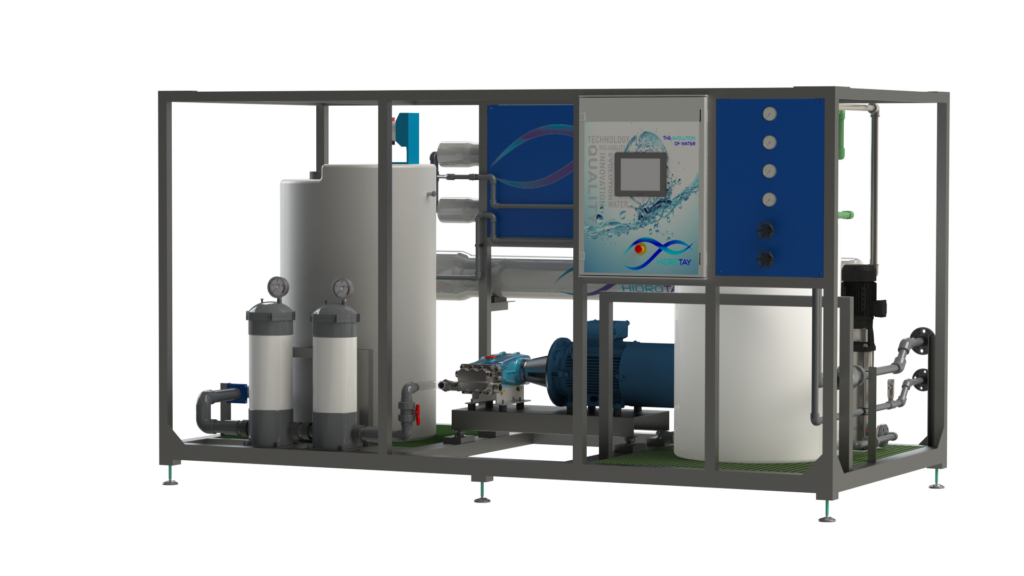

Desalination System for Fish Processing Plant

At this fish processing plant located on the coast, we have implemented an advanced desalination system to address the water supply needs efficiently and cost-effectively. Our cutting-edge solution utilizes a reverse osmosis process to produce up to 400 m³ of desalinated water per day, ensuring an adequate supply for the plant’s daily operations.

Additionally, like all our equipment, it offers continuous monitoring of key process parameters, access to our vigData platform for remote system operation control, automatic alerts for potential anomalies, and a highly skilled technical support team available to provide assistance at all times.

In addition to providing a constant supply of high-quality water, our desalination system offers significant cost savings to the plant. Given the large volume of water consumed in fish processing operations, the cost of acquiring conventional freshwater could be substantial. However, with our desalination technology, the plant can economically leverage the abundant seawater reserves available on the coast.

Our desalination system is designed to deliver optimal performance with minimal maintenance, ensuring a rapid and enduring return on investment. By choosing our solution, the fish processing plant not only ensures a reliable water supply but also enhances its operational efficiency and reduces its economic and environmental impact in the area.

Interested in how we can assist with your next project?

CONTACT US NOW!

Calle Colexio Paraixal, 5, 36216 Vigo (Pontevedra)

CANARY ISLANDS BRANCH

Idamar Atlantic, S.L.